Heavy-duty alignments are slow when you’re fighting with lifts, complicated multi-axle setups, and software that wasn’t built for trucks. This alignment machine fixes all of that by aligning on ramps, pits, or a flat bay—no vehicle lifting required. Four industrial HD cameras and WideScope® imaging deliver ±0.01° accuracy, so you cut comebacks and finish jobs right the first time. It handles wheelbases up to 50 feet and vehicle widths up to 13 feet, so semis, buses, and trailers are fair game. If you need a dependable wheel alignment machine that speeds up throughput without sacrificing precision, this is it.

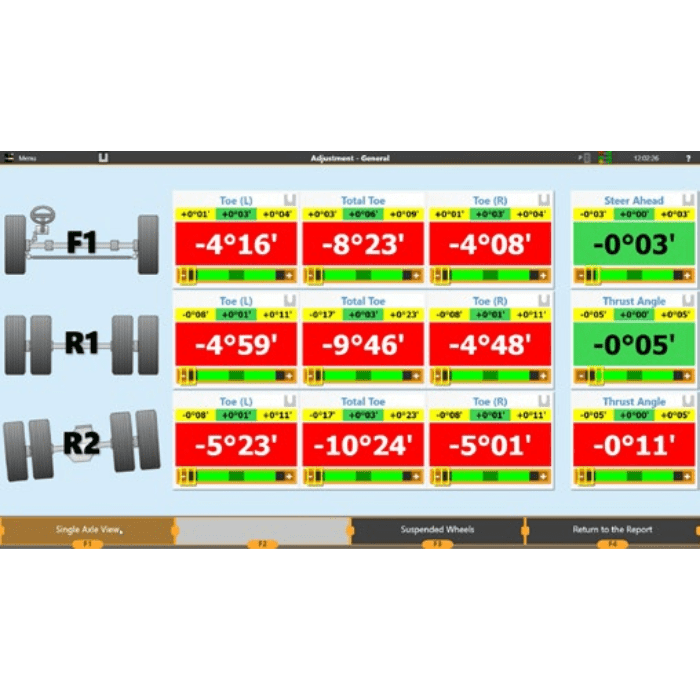

You’ll set up quicker with eight lightweight imaging targets and adjustable clamps that fit 15″–27″ rims, including wide duals. The TechnoVector 7 Truck software runs on Windows, giving your team a familiar interface with step-by-step workflows and clear on-screen graphics. Real-time measurements guide every adjustment, and live reporting keeps your customer conversation simple and professional. Align up to four axles at once and measure camber, caster, SAI/KPI, thrust angle, and more with repeatable accuracy. In short, this auto alignment machine is built for busy commercial bays that can’t afford downtime.

For fleets and high-volume shops, the built-in database of 42,000+ vehicle specs (with annual update options) means you’re rarely starting from scratch. Rolling, forward, jacking compensation, and suspended-wheel modes help you handle real-world conditions without slowing the day. The system is CE certified and powered by a straightforward 120V, 15A, single-phase connection, making installation and service painless. You’ll also get storage stands, heavy-duty turntables, a PC cabinet, and all the essentials to keep the bay tidy. If you’ve been waiting for a tire alignment machine designed for trucks, buses, semis, and trailers, you’ve found it.

If this isn’t what you need, explore our other Wheel Alignment Machines.