In this guide, we’ll explore how to safely work around common auto lift installation problems like sloped concrete, thin slabs, or post-tensioned foundations. By the end, you’ll know your options and how to address a garage floor that’s less-than-ideal for a lift.

Quick Navigation

-

Why Floor Conditions Matter for Lift Safety

- Standard Concrete Requirements (Baseline)

- Challenges of Uneven Floors

- Thin Slabs: Risks and Fixes for Car Lifts

- Installing on Post-Tension Slabs (PT)

- Alternative Solutions for Imperfect Floors

- Additional Resources

- Conclusion

Why Floor Conditions Matter for Lift Safety

Vehicle lifts push thousands of pounds through their columns into a small footprint on your concrete slab. If the floor is weak, uneven, or unstable, it directly jeopardizes the lift’s stability and safety. Your slab is literally the foundation of a secure, wobble-free installation.

What the Specs Require

-

Follow manufacturer car lift concrete requirements (minimum thickness and compressive strength) to handle concentrated loads without cracking or shifting.

-

Ensure the slab is level, sound, and uniformly supported so column baseplates bear evenly.

-

Verify the floor meets published specs before installation—don’t assume; measure and document.

Real-World Risks If You Ignore It

-

A non-compliant slab can let the lift tip, settle, or collapse under load.

-

Damage escalates fast: bent steel, cracked concrete, and vehicle or personal injury risk.

-

Fixing a bad floor after install costs far more than prepping it correctly up front.

👉 For shop owners, review our Car Lift Safety Guide for OSHA/ALI-compliant best practices.

Bottom Line

Bad floor conditions raise accident risk; a proper, spec-compliant slab keeps your lift rock-solid. Never cut corners on the floor—protect your equipment, vehicles, and people. Address issues before install and you’ll have confidence every time you raise a car. Not sure if your slab qualifies? Contact Pitstop Pro with your slab thickness and vehicle details, and we’ll give you a tailored recommendation.

Standard Concrete Requirements (Baseline)

For most home and light-duty shops, the typical 2-post lift floor requirements are a single, continuous slab that’s at least 4″ thick with 3,000 PSI concrete. That spec comfortably supports many 7,000–10,000 lb lifts, provided the slab is sound and level. Step up in lift capacity and you’ll need beefier concrete—think 6″ thickness and ~3,500+ PSI for many 12,000 lb and up models.

Baseline Specs (Quick Reference)

-

Standard 2-post (≤ ~10k lbs): ~4″ slab, 3,000–3,500 PSI; fully cured (28+ days); rebar strongly recommended.

-

Heavy 2-post / 4-post (12k–15k lbs): ~6″ slab, 3,500+ PSI; some 16k+ lifts may call for 8″.

-

Reinforcement: Rebar or wire mesh increases strength and limits cracking; a reinforced 4″ is safer than an unreinforced 4″.

-

No seams under posts: Keep columns off control joints, cracks, or cold joints; pour a proper pad if a post location intersects one.

Four-post lifts spread load across four feet, so many garage-style models don’t require anchoring when placed on a level 4″ / 3,000 PSI slab. That lower load per foot is why they feel stable free-standing in typical home setups. Always check the manual—heavy-duty 4-posts and alignment racks may still recommend anchors.

4-Post Notes

-

Stable without bolts on a sound, flat slab; leveling and runway setup matter as much as thickness.

-

Anchor when advised for high-capacity use, aggressive shop workloads, or if your floor conditions are marginal.

-

Practical benefit: Free-standing setups preserve flexibility (e.g., caster kits) while still feeling rock-solid on spec concrete.

If you’re unsure your slab meets spec, verify before install. Measure thickness with a careful test hole or pull building plans, and assume older, intact slabs are usually around 3,000 PSI unless you have reason to doubt it. When in doubt, prep or pour a pad now—it’s cheaper than repairing a cracked slab or a damaged lift later.

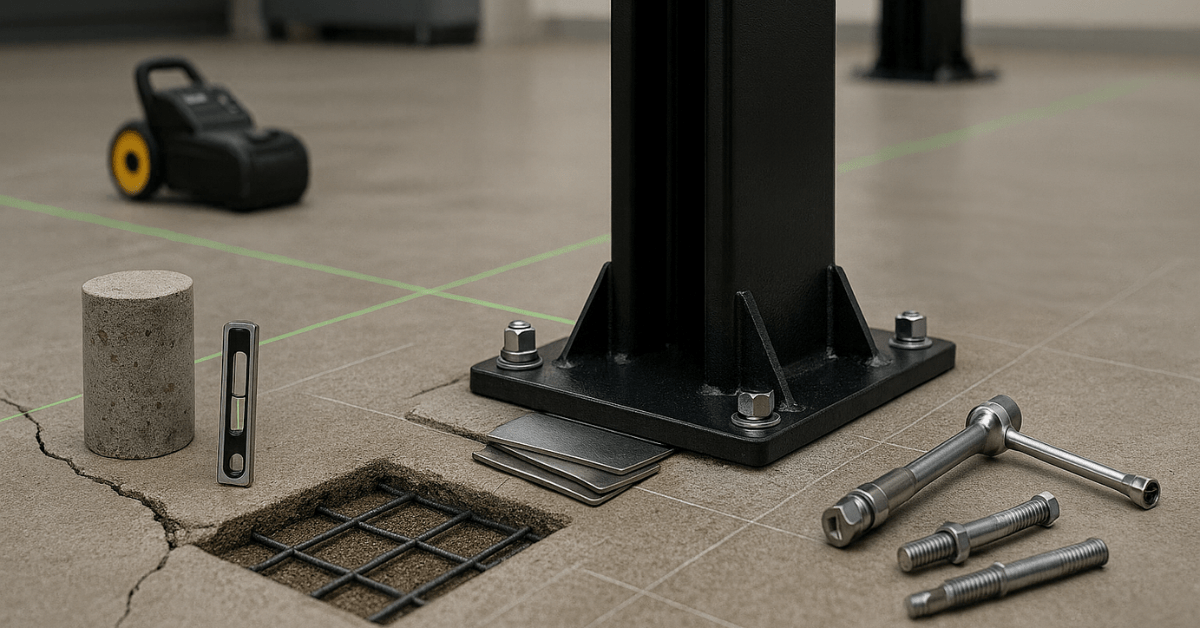

Challenges of Uneven Floors

Many garages have a slight drainage slope, which is manageable, but significant unevenness is a safety risk for any vehicle lift. When one post sits lower, the columns aren’t plumb to each other, weight shifts to a single side, and geometry goes out of spec. Even a 1″ height difference can create a visibly sloped lift—inviting vehicle creep, poor lock engagement, and overstressed anchors.

Why It Matters (Real-World Effects)

-

Tilted posts = uneven weight distribution and higher load on one column.

-

Pads and arms won’t stay level, so the vehicle can slide or shift during raise/lower.

-

Safety locks may not engage simultaneously, reducing redundancy.

-

Anchor bolts and baseplates see extra stress, shortening service life.

Most installers treat aggressive shimming as a red flag—once you need more than about ½″ of shims under any column, the floor isn’t suitable as-is. Thick shims also reduce anchor embedment (a 1″ shim means 1″ less bolt in concrete), which weakens the connection. Bottom line: get the posts plumb and parallel first, then everything—locks, arms, runways—works as designed.

Fixes That Work

-

Professional floor leveling: Grind high spots or install a leveling compound/epoxy; for severe cases, cut and repour a level pad so columns share load evenly.

-

Manufacturer-approved steel shims (light correction): Use small, full-footprint metal shims (e.g., 1/16″–1/8″) to fine-tune plumb; never wood or improvised materials, and stop if stacks grow.

-

Relocate the lift: Check multiple spots; a flatter corner may solve the issue without concrete work (verify ceiling and door clearance).

-

Anchor + shim combo (pro-guided): Anchor at the low end and minimally shim the high end; use longer anchors if needed and torque to spec.

Warning: Do not install a lift on a dramatically sloped floor without remediation. It might be tempting to “make it work” by shimming one side a lot, but as noted, beyond ~½″ of shimming, you’re asking for trouble. The lift may operate, but the geometry is off – locks may not engage simultaneously, the car may sit at an angle, and structural stresses aren’t balanced. In short, the lift won’t be as safe or as stable as it should be. Always prioritize getting the columns level and parallel to each other for safe lifting.

Not sure if your garage floor qualifies? Reach out to us directly at support@pitstop-pro.com or 470-208-2754 for quick guidance.

Thin Slabs: Risks and Fixes for Car Lifts

A slab that’s too thin or weak for anchors is a safety hazard—period. When concrete is under-spec (e.g., only 2–3″ thick or unreinforced), it can’t distribute post loads or hold anchors properly. The result can be cracking, anchor pull-out, wobble, or sudden failure.

Why Thin Slabs Fail

-

Cracking/Breakage: Concentrated post loads fracture undersized slabs; cracks often radiate from anchor points.

-

Anchor Pull-Out: Shallow embedment and low concrete mass let wedge or adhesive anchors rip free under tension.

-

Flexing/Instability: Thin concrete deflects, making posts lean and the lift wobble—dangerous with a vehicle overhead.

Not sure if your shop needs an upgrade? Browse our Scissor Lifts for floor-friendly alternatives.

Red Flags Your Floor Is Under-Spec

-

Measured thickness below the manufacturer’s minimum (e.g., 2–3″).

-

Anchors that spin, won’t torque, or “crumble” the hole.

-

Visible deflection, spreading cracks, or a spongy feel under load.

-

Unreinforced slab where rebar/mesh was expected.

Safe Fixes (What Works)

-

Pour reinforced footings/pads: Saw-cut 3′×3′ or 4′×4′ at each post, dig to required depth, and pour 6″+ high-strength, rebar-tied pads; mount posts after full cure.

-

Re-slab or thicken the area: Bonded topping or full repour to bring thickness/PSI and reinforcement up to spec.

-

Engineer-approved anchors/configs: Only as cleared by the lift maker/installer; many will still require new concrete for safety.

What Not to Do

-

No “quick patches”: Epoxy alone won’t fix inadequate concrete; it helps grip, not slab capacity.

-

No steel plates as a shortcut: Plates spread load a bit but can’t make a 2″ slab act like 4–6″.

-

No tall shim stacks: They don’t add thickness and reduce anchor embedment and strength.

Call the Pros First

-

Verify thickness (careful test hole or plans) and concrete quality before installation.

-

Ask the manufacturer/installer about approved remedies (e.g., longer anchors, through-bolting with backing plates, or capacity limits) and warranty implications.

-

Expect the common recommendation: pour new concrete to meet spec and protect coverage.

Bottom Line

If your slab is too thin, fix the floor before you set the lift. The cost of proper pads or a re-slab is far less than a failed anchor, a dropped vehicle, or voided warranty. Safety first—build the foundation right and your lift will do the rest. Have questions about your slab or which lift will fit? Call us at 470-208-2754 and we’ll help you plan the safest solution.

Installing on Post-Tension Slabs (PT)

Post-tension slabs contain steel tendons under heavy tension, which makes blind drilling a hard no. One misplaced hole can snap a cable, blow out concrete, and compromise the slab. Assume PT until proven otherwise, and get a qualified pro to verify before you plan any anchors.

How to Confirm PT (Safely)

-

Look for “POST TENSIONED” stamps/placards near the garage door or along slab edges.

-

Check closing docs, builder plans, or city records for structural notes on PT.

-

Hire a structural engineer to review plans and scan the slab (GPR/X-ray) to map tendon paths.

-

Expect a written, stamped recommendation: no-drill vs. precisely where/what depth is allowed.

-

Keep the tendon map and approval with your lift records for warranty/insurance.

A no-drill setup is the default for most homeowners with PT. Free-standing 4-post lifts feel stable on a sound, level slab when set up per the manual, and caster kits preserve mobility. Scissor and low-rise pad lifts sit on the surface, making tire/brake/undercar work easy with zero holes in the concrete.

No-Drill Options & Setup Tips

-

Free-standing 4-post: Level the runways, drop locking feet, and chock as instructed; add a caster kit for repositioning.

-

Scissor / low-rise pad lifts: Great for service work in tight bays; verify floor flatness and pad contact.

-

Mobile column lifts: High-capacity and anchor-free; better for trucks/fleets, higher cost.

-

Portable 2-post with shallow anchors: Only if an engineer maps safe zones/depths—otherwise choose a true no-drill option.

-

Keep the floor flat, clean, and level; follow load ratings and operating procedures to the letter.

If you absolutely must anchor a full-height 2-post, treat it like a mini engineering project. Budget for scanning, an engineered plan, and strict hole-depth control—shortcuts aren’t acceptable on PT. In many home garages, the cost/complexity tips the decision back to a no-drill lift.

Engineered Anchoring (Pro-Only Workflow)

-

Map tendons with GPR/X-ray and paint the safe zones; get an engineer’s stamped plan.

-

Use only the specified anchor type and engineer-limited embedment depth with drill stop collars.

-

Drill precisely in marked locations; vacuum and prepare holes exactly as the anchor spec requires.

-

Torque/proof-test anchors to spec; retorque after initial cycles if required by the plan.

-

Document everything (scan report, layout, torque logs) for inspections, warranty, and insurance.

Bottom line: With PT slabs, no-drill solutions are safest and simplest; if anchoring is unavoidable, make it fully engineered—no guesses, no “just one more hole.”

Alternative Solutions for Imperfect Floors

Not every setup needs a full-height, anchored 2-post. If your slab is thin, sloped, or post-tensioned, picking the right lift style can solve the problem without risky drilling. Start with your goal—storage vs. frequent wrenching—and choose the option that works with your floor, not against it.

Free-Standing 4-Post (Storage-Focused)

A four-post spreads weight across four corners and typically feels stable on a sound, level 4″/3,000-PSI slab. It’s ideal for stacking cars and light maintenance without anchors or concrete drama. Add a caster kit if you want mobility in a small garage.

-

Level runways and drop locking feet per the manual.

-

Use minimal shims so all corners bear evenly.

-

Great first choice for PT slabs or marginal concrete.

Portable Low-/Mid-Rise Scissor Lifts

These floor-sitting lifts handle brakes, tires, and suspension work without permanent holes. They roll out when needed and tuck away when space is tight. Broad contact patches help distribute load on thinner slabs (within rated limits).

-

Verify floor flatness and pad contact before lifting.

-

Follow rated capacity and OEM lift points.

-

Perfect for rentals or “no-drill” properties.

Plan-Ahead Concrete Upgrades (Dedicated Pads)

If you’re building or renovating, concentrate strength where posts will sit. Reinforced footings or thickened strips let you run almost any lift later. It’s a one-time project that future-proofs the bay.

-

Tie pads into the surrounding slab with rebar.

-

Respect cure times before anchoring.

-

Document specs for warranty/insurance records.

No-Lift & Mini-Lift Alternatives

When a big lift isn’t practical, you can still work safely and efficiently. Portable electric jack systems and high-reach stands cover routine service without anchors. You keep flexibility and avoid slab modifications.

-

Always chock wheels and use proper cribbing.

-

Consider ventilation and safety if exploring service pits.

-

Good stopgap until a proper pad or new slab is poured.

Quick Match Guide

Pick based on use-case and floor constraints, then move forward confidently. Most homeowners with PT or questionable slabs are best served by no-drill solutions first. If you later upgrade the concrete, a 2-post becomes an option.

-

Mostly storage, light service: Free-standing 4-post (+ caster kit).

-

Frequent under-car work, low ceilings: Mid-rise scissor.

-

PT slab / can’t drill: Any no-drill option above.

-

Planning a 2-post later: Pour reinforced pads now.

Additional Resources

For more detailed information and guidance, check out these resources:

-

Installation Requirements Guide – Pitstop-Pro Blog: A comprehensive guide on lift installation prep (concrete, electricity, spacing). Covers concrete thickness, curing, anchoring tips, and more in depth.

-

2-Post Lift Collection – Browse Pitstop-Pro’s range of two-post lifts (with specs and requirements listed for each).

-

4-Post Lift Collection – Explore various four-post lifts, from parking models to heavy-duty alignment racks.

-

ANSI/ALI Lift Installation Standards – Overview of the ANSI/ALI ALIS standard (2022) which governs automotive lift installation and service safety. It’s the go-to industry guideline referenced by OSHA and lift manufacturers.

-

OSHA Automotive Lift Safety – OSHA’s guidance (via the General Duty Clause) emphasizes following manufacturer instructions and consensus standards for lift safety. In short, OSHA defers to standards like ALI – meaning things like proper anchoring, no damaged concrete, and regular inspections are not just good ideas, they’re expected for workplace safety.

Conclusion

Imperfect floor? You can still own a lift—safely—if you pick the right approach. Safety is non-negotiable: fix thin/uneven concrete or choose a lift that doesn’t require anchors (especially on post-tension slabs). A little prep now costs far less than a cracked slab, failed anchor, or damaged vehicle later.

Key Takeaways

-

Follow manufacturer concrete specs (thickness, PSI, cure time) and never “make do.”

-

Uneven slabs: keep shims minimal and get posts plumb/parallel—or level the floor.

-

Thin slabs: pour reinforced pads or re-slab; epoxy/plates aren’t structural fixes.

-

Post-tension: avoid drilling; pick no-drill options or use engineered, scanned anchor plans.

-

When unsure, pause the install and consult a pro—safety beats speed every time.

If you’re not certain about your floor, get it checked before you drill the first hole. A pro can verify thickness, PSI, and level, and advise on pads or placement; many will do a small test hole or scan for PT tendons. Always read your lift’s manual cover-to-cover and document measurements for warranty/insurance.

Quick Pre-Install Checklist

-

Measure slab thickness at each post location and confirm PSI/cure (28+ days).

-

Check for seams, cracks, or joints under posts; relocate or pour pads if needed.

-

Verify level across all feet; plan minimal, full-footprint steel shims only.

-

For PT slabs, obtain GPR/X-ray mapping and an engineer-stamped anchor plan—or go no-drill.

-

Stage tools/anchors to spec and torque-log everything at install.

At Pitstop-Pro, we match lifts to real-world floors—old, cracked, thin, or post-tensioned—and recommend safe, practical setups. Whether you need storage, frequent wrenching, or a hybrid solution, we’ll point you to the right equipment and floor strategy. You’ll lift with confidence, not crossed fingers.

-

[Contact our experts] for floor review guidance, model picks, and install best practices (or email support@pitstop-pro.com).

With a sound plan and the right lift, an imperfect floor doesn’t stop you—it just informs smarter choices. Do it right once, and enjoy years of safe, smooth lifting with peace of mind.

Leave a comment